The Challenge: Protecting Motherboards during Shipping

The company faced significant challenges with its existing packaging solution for a large, delicate motherboard used in high-end technology products. The previous approach involved a combination of corrugated boxes reinforced with EPE and EVA foam. However, key issues included:

- Recyclability Limitations: Certain materials were glued together, making proper recycling nearly impossible.

- Transport Damage: The previous packaging design did not adequately safeguard the product, leading to costly damage during transit.

- Environmental Impact: The non-optimized design increased material waste and carbon footprint.

The organization needed a streamlined solution that could enhance product protection, improve recyclability, and reduce costs.

Nefab's Solution: Hybrid Packaging Innovation with HDPE Thermoformed Reflex Components

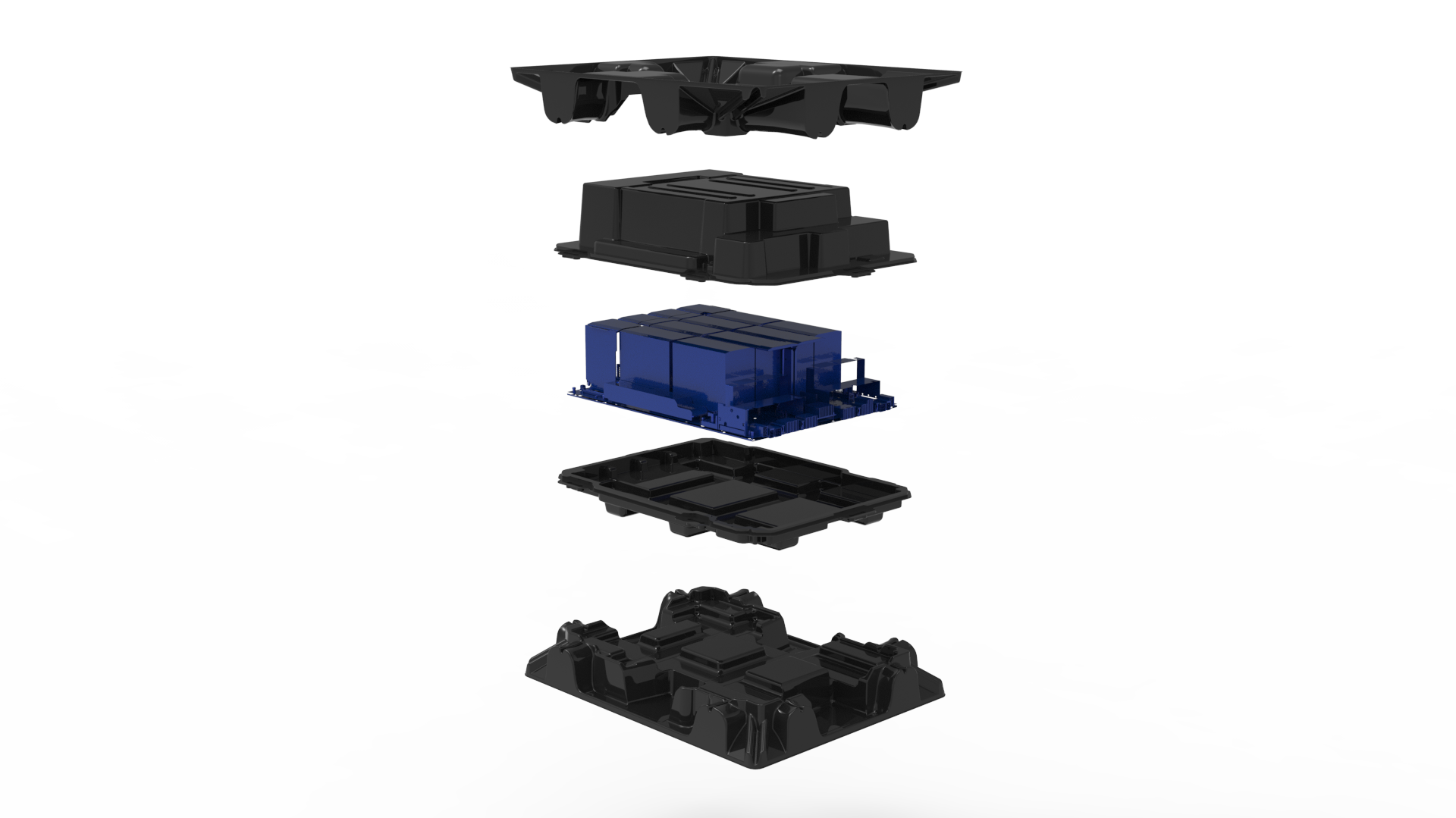

The packaging solutions provider delivered a groundbreaking hybrid design that significantly outperformed its predecessor. Key elements of the solution included:

- HDPE Thermoformed Reflex Components: The design featured a clamshell structure to hold the motherboard securely, supplemented by Reflex cushioning components for comprehensive protection. These elements were crafted from 100% recycled HDPE that is fully recyclable.

- Optimized Corrugated Box: A better-structured outer box offered enhanced strength and reduced material usage.

- Anti-Static LDPE Bag: To further safeguard the sensitive electronics, a protective anti-static bag was incorporated into the design.

This innovative solution not only reduced environmental impact but also enhanced the product’s safety during transit.

The Results: Reduction in CO2 Emissions with Increased Cost Efficiency and Enhanced Protection

The new packaging design delivered remarkable results:

- Sustainability Boost: Achieved a 27% reduction in CO2 emissions due to the use of recyclable and lightweight materials. Eliminated recycling barriers by replacing glued components with easily separable materials.

- Cost-Efficiency: Achieved a 10% reduction in overall packaging costs through material optimization and reduced weight.

- Enhanced Protection: Significantly decreased product damage during shipping, reducing costly returns and preserving brand reputation.

Ready to Transform Your Packaging and Supply Chain

Shipping delicate motherboards requires a solution that enhances protection, boosts sustainability, and cuts costs. Our hybrid packaging, featuring HDPE thermoformed Reflex components and an optimized corrugated box, delivers on all fronts. For a leading technology partner, this design reduced CO2 emissions by 27%, cut packaging costs by 10%, and significantly decreased transit damage.

Talk to Our Experts

Learn More About our Solution for the Datacom Industry

Discover our full range of innovative packaging for the datacom and cloud industry..

Explore the Datacom Solutions Page

Discover packaging and logistics solutions designed specifically for the Datacom industry.

Related Datacom Customer Cases

- Sustainable Packaging for GPUs: Discover our eco-friendly approach to shipping high-value Graphics Processing Units.

- Innovative Packaging for POS Hardware: Discover how Nefab’s lightweight foam pallets helped a leading tech firm save $2.5 million annually and slash CO2 emissions by 572 metric tons. By optimizing container capacity and logistics for POS hardware, we helped them achieve a more sustainable, cost-effective supply chain

Datacom Industry Insights

Additional Resources